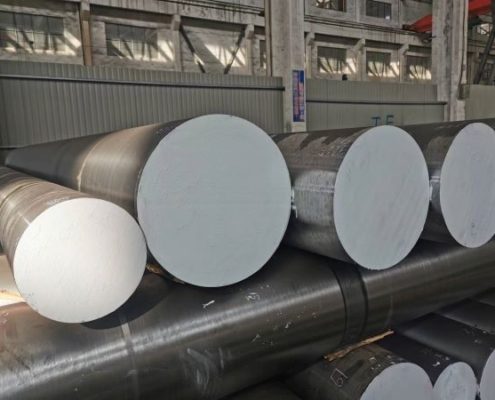

C55 | DIN1.0535 CARBON STEEL

C55/DIN 1.0535 Carbon Steel manufacturers and suppliers,supplied in round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

C55/DIN1.0535 carbon steel is a medium carbon steel according to EN10083 and EN 10250 standard.It is usually supplied in an untreated or normalized condition for simple common application ,and also used in quenched and tempered condition for industrial applications. C55/DIN1.0535 steel is widely used for less exacting springs, shafts, bushings, crankshafts, etc.

C55 Steel Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni |

| C55/DIN 1.0535 | 0.52-0.6 | 0.6-0.9 | ≤0.4 | ≤0.045 | ≤0.045 | ≤0.4 | ≤0.1 | ≤0.4 |

Remark:Cr+Mo+Ni≤ 0.63%

C55 Steel Related Specifications

AISI/SAE: 1055

BS:070M55 / EN9

JIS / KS:S55C

Heat Treatment For C55 Steel

- Normalizing:825℃-885℃,Cool in air

- Annealing:770-810℃,Cool in furnace

- Hardening:810 – 850°C,oil quench is recommended

- Tempering:550°C – 660°C, cool in still air

C55 Steel Mechanical Property with Normalized and Tempered condition as per EN10250

| Thickness,mm | Tensile,Mpa | Yield,Mpa | Elongation,% |

| ≤100 | ≥640 | ≥330 | L:≥12 T:- |

| 100-250 | ≥620 | ≥300 | L:≥12 T:≥9 |

| 250-500 | ≥600 | ≥260 | L:≥12 T:≥9 |

| 500-1000 | ≥590 | ≥250 | L:≥11 T:≥8 |

C55 Steel Mechanical Property with Quenched and Tempered condition as per EN10250

| Thickness,mm | Tensile,Mpa | Yield,Mpa | Elongation,% |

| ≤70 | ≥700 | ≥420 | L:≥15 T:- |

| 700-160 | ≥630 | ≥360 | L:≥17 T:≥11 |

| 160-330 | ≥610 | ≥330 | L:≥16 T:≥10 |

Hardness Requirements for C55

- Treated to improve shearability(+S):≤255HBW

- Soft annealed(+A):≤229HBW

- Flame or induction hardening: Min 58HRC

- Water quenching hardness:60-65HRC

C55 Steel Tempering Temperature Vs Hardness

| Quenching | Tempering Temperature,ºC | ||||||||

| Temperature,ºC | Hardness,HRC | 150ºC | 200ºC | 300ºC | 400ºC | 500ºC | 550ºC | 600ºC | 650ºC |

| 820ºC | 62-63 | 63 | 56 | 50 | 45 | 34 | 30 | 24 | 21 |

C55 Steel Quality Certification

A material test report(Inspection Certificate EN 10204 3.1) will be provided, documenting the following:

1.Chemical analysis

2.Mechanical properties

3.Surface hardness

4.Non Metallic Inclusion

5.Heat Treatment Process

6.Grain size

7.Forging ratio

8.Ultrasonic test report

C55 Steel Supply Size & Condition

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.16 – 250mm with UT Assurance

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled