AISI 4130 STEEL | 25CRMO4 | DIN 1.7218 | SCM430

As a low carbon chromium-molybdenum alloy steel in ASTM A29, AISI 4130 steel has excellent weldability, machinability and moderate hardenability.

After quenching and tempering heat treatment, AISI 4130 steel further acquires higher strength and hardness, as well as better corrosion and fatigue resistance.

AISI 4130 steel is usually used in quenched and tempered condition with hardness 207-235HB(18-22HRC).

AISI 4130 Steel Application

- Aerospace: aircraft structural parts, aircraft oil pipes, frames and accessories

- Automotive industry: racing car frames, roll cages, car frames

- Machinery manufacturing: shafts, spindles, steering wheels, bolts, studs, gears

- Chemical industry: welded parts, welded structures composed of plates and pipes, high-pressure pipes

- Oil and gas industry: transportation pipes, drill pipes

AISI 4130 Steel Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

AISI 4130 Steel Equivalent Grade

Europe-EN10083/EN10250 UK-BS970 China-GB 3077 Japan-JIS G4105

25CrMo4/1.7218 708A25 / 708M25 30CrMoA SCM430

AISI 4130 STEEL FORGING

- Initial Forging Temperature:1150-1200℃

- Final Forging Temperature: >850℃

- Forging Ratio:above 4:1

- Post-Forging Treatment:Cooling in sand slowly or furnace cooling after forged.For 4130 steel with large cross-section size, annealing after forging is recommended.

AISI 4130 Steel Heat Treatment & Mechanical Property

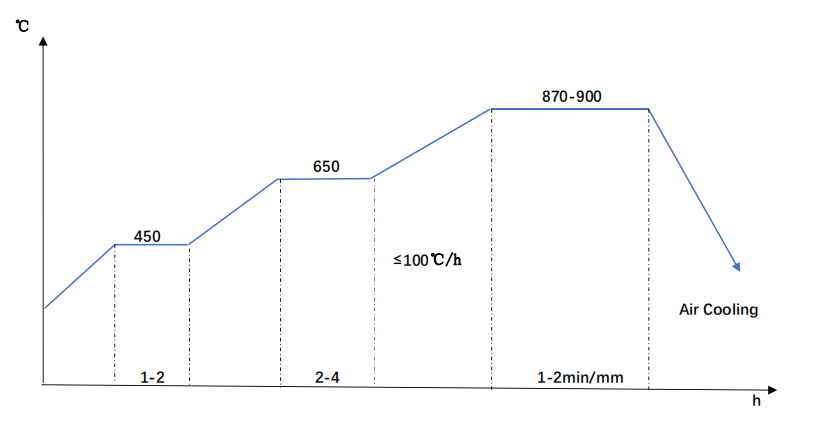

- Normalizing:870℃-900℃,air cooling

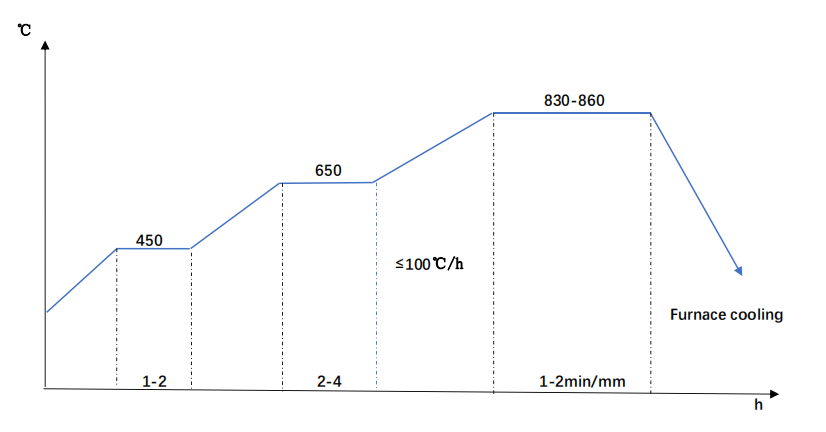

- Annealing:830℃-860℃,furnace cooling

AISI 4130 Steel Normalizing Diagram

AISI 4130 Steel Annealing Diagram

AISI 4130 Steel Normalizing & Annealing Mechanical Property

| Temperature | Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness | |

| AISI 4130+N | 870°C | ≥670Mpa | ≥435Mpa | ≥25.5% | ≥60% | ≥86 J | 197HBW |

| AISI 4130+A | 860°C | ≥560Mpa | ≥360Mpa | ≥28.2% | ≥56% | ≥62 J | 156HBW |

- Quenching:870-890°C,oil quench,Quench hardness:50-55HRC

- Tempering:650-700°C, cool in still air,Tempering hardness:18-22HRC

AISI 4130 steel Quenching Critical Diameter

| static oil | 20°C Water | 40°C Water | 20°C 5% Sodium chloride solution |

|

| Critical Diameter,mm | 15 | 28 | 24 | 29 |

AISI 4130 steel 60K/75K Level Mechanical Property In Quenched & Tempered Condition

| Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Hardness HB | Impact Charpy-V, -18ºC,J | |

| 60K | ≥ 586 | ≥ 420 | ≥ 18 | ≥ 35 | 174-237 | ≥ 42 |

| 75K | ≥ 655 | ≥ 517 | ≥ 17 | ≥ 35 | 197-237 | ≥ 33 |

AISI 4130 Steel Quality Certification

A material test report(Inspection Certificate EN 10204 3.1) will be provided, documenting the following:

1.Chemical analysis

2.Mechanical properties

3.Surface hardness

4.Non metallic inclusion

5.Heat treatment report

6.Grain size

7.Forging ratio

8.Ultrasonic test report

Supply Size & Condition For AISI 4130

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.14 – 350mm with UT Assurance

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled