Professional Special steel manufacturer-FUHONG

No matter what kind of carbon steel,you can get professional quality assurance here

The main chemical element Carbon which is in the range of 0.12–2.0% is defined as Carbon steel.It only allows other elements which are manganese (1.65% max), silicon (0.60% max), and copper (0.60% max).Other elements may be present in quantities too small to affect its properties.Steel with a low carbon content has the same properties as iron, soft but easily formed. As carbon content rises the metal becomes harder and stronger by heat treatment, but less ductile and more difficult to weld. Higher carbon content lowers steel’s melting point and its temperature resistance in general.

WHAT WE SUPPLY?

Hot Forged Products

- Round : Dia.80 – 1,200mm

- Flat / Square : Thickness Max.800mm

- Rings,Tubes,Shafts, Rollers, Blocks: Customized or According to Drawing

Hot Rolled Products

- Round : Dia.16 – 300mm with UT quality assurance

- Other Shapes:Customized

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

Heat Treatment: Quenching & Tempering (+QT),Normalizing (+N), Annealing (+A),Stress Relieving(+SR)

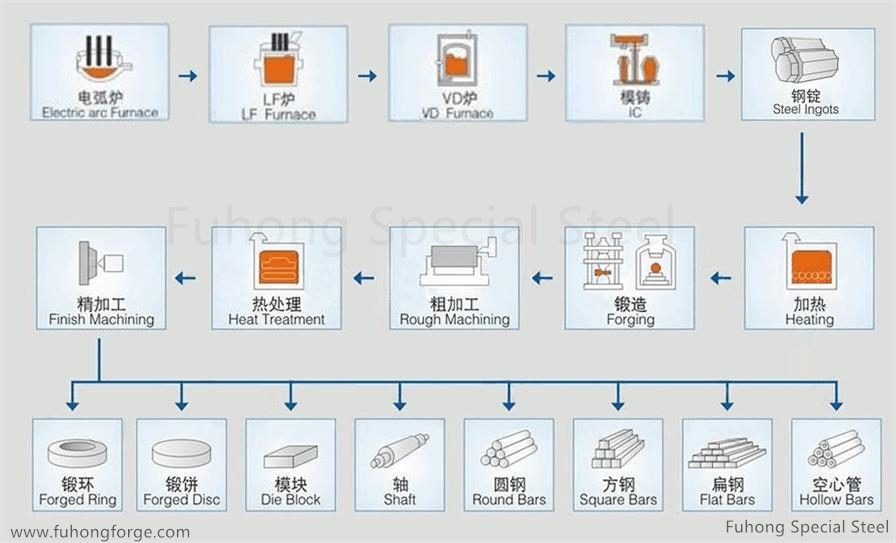

HOW WE SUPPLY?

OUR CORE CARBON STEEL PRODUCTS

PRINCIPLES FOR SELECTING CARBON STEEL

Compared with alloy steel, carbon steel has a simpler and clearer composition, with the main elements consisting of carbon, silicon and manganese.

Carbon steel is affordable while still providing excellent mechanical properties.It is widely used in various industries and is a common choice for various purposes.Therefore, how to choose the right carbon steel material for different industry needs is particularly important.

- Choose carbon steel material according to product performance requirements

The performance requirements of steel include strength, toughness, hardness, wear resistance, etc.

Generally speaking, the higher the carbon content in carbon steel, the greater the hardness and strength, but the lower the plasticity and toughness.Therefore, if the required product requires high strength and hardness, low carbon steel should be avoided.On the contrary, if the required product pays more attention to good ductility and toughness, low carbon steel is a good choice.

- Choose carbon steel material according to product process requirements

When we choose carbon steel, we should not only consider the performance properties of the material, but also consider whether the material is suitable for further processing, that is, the process performance.

For carbon steel, we have to consider the following issues when making a choice.

1.Does the carbon steel have good hot and cold formability?

2.Does the carbon steel easy to be machined?

3.Does the carbon steel easy to be welded?

4.Does the carbon steel need to be heat-treatable?

5.What kind of application is required for the selected carbon steel material?

When we think about the above questions clearly, I believe there will be a clear answer in our minds to guide our next work.

- Consider production costs and material prices

When we choose carbon steel to make products, we are actually considering its cost. Indeed, for the design and selection of materials, it is necessary to ensure its economic applicability while meeting the product requirements in advance, rather than blindly choosing higher-grade materials or simply replacing inferior ones with superior ones.

CARBON STEEL GRADE LIST

| AISI/SAE | DIN/EN | BS | JIS/KS |

| 1015 | C15 / 1.0401 | 080M15 | S15C |

| 1018 | S17C | ||

| 1020 | C22 / 1.0402 | 070M20 / EN3 | S20C |

| 1025 | C25 / 1.0406 | 070M26 | S25C |

| 1030 | C30 / 1.0528 | 080M32 / EN5 | S30C |

| 1035 | C35 / 1.0501 | 070M36 | S35C |

| 1040 | C40 / 1.0511 | 080M40/EN8 | S40C |

| 1045 | C45/1.0503 | 080M46 | S45C |

| 1050 | C50 / 1.0540 | 080M50 | S50C |

| 1055 | C55 / 1.0535 | 070M55/EN9 | S55C |

| 1060 | C60/1.1221 | 070M60 | S58C |