Your Reliable Business Partner-FUHONG STEEL

No matter what kind of alloy steel, you can find the solution here

Alloy steel referring to low alloy steel is contained with a variety of elements which are added strictly in addition to the carbon.Typical alloyed elements are Molybdenum, Manganese, Nickel, Silicon, Aluminium, Chromium, and Vanadium.They are used to improve its mechanical or physical properties,such as wear resistance,strength, hardenability,corrosion resistance,ductility, formability, weldability and so on.Alloy steel is widely used in oil and gas,aerospace,automotive, wind power and defense industries etc.

WHAT WE SUPPLY?

Hot Forged Products

- Round : Dia.80 – 1,200mm

- Flat / Square : Thickness Max.800mm

- Rings,Tubes,Shafts, Rollers, Blocks: Customized or According to Drawing

Hot Rolled Products

- Round : Dia.16 – 300mm with UT quality assurance

- Other Shapes:Customized

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

Heat Treatment: Quenching & Tempering (+QT),Normalizing (+N), Annealing (+A),Stress Relieving(+SR)

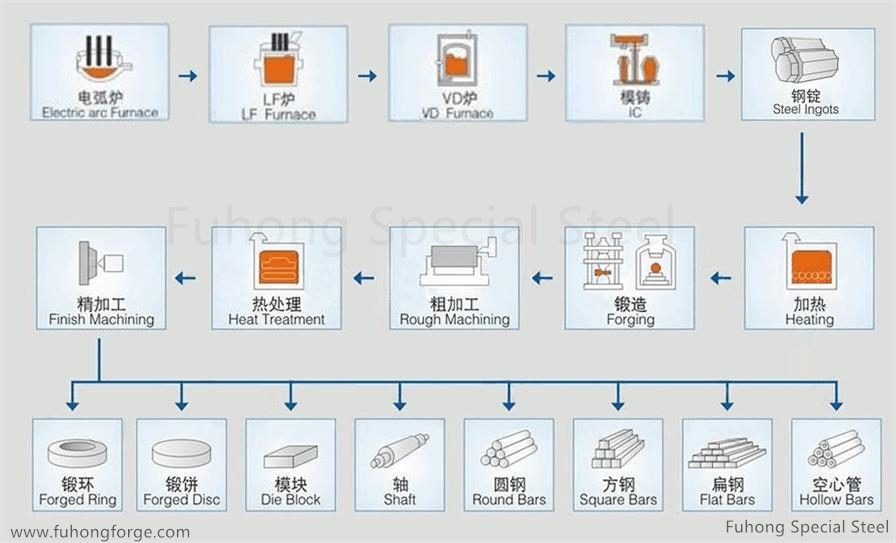

HOW WE SUPPLY?

OUR CORE ALLOY STEEL PRODUCTS

PRINCIPLES FOR SELECTING ALLOY STEEL

The selection of alloy steel, like other types of materials, is a relatively complex issue, and it is an extremely important part of the design of various mechanical products.

In order to produce high-quality products, comprehensive consideration must be given to the structural design of the product, alloy material selection, hot and cold processes, and production costs.

Correct and reasonable selection of alloy materials is the basis for ensuring the best performance, working life, safety and economy of products. The general principles for the selection of alloy materials are now introduced as follows:

- Meet the performance requirements of the products

The performance of the material refers to the performance that the material must have to ensure the normal operation of the product. It includes mechanical properties, physical properties and chemical properties.

Various mechanical products, due to their different uses, working conditions and other factors, also have different requirements for their components, which can be expressed as the following three types of differences.

- Stress condition:Load properties (static load, dynamic load, alternating load),Stress form (tension, compression, bending, torsion, shear), Distribution (concentrated distribution, uniform distribution) and Strength, Stress condition.

- Working environment: Temperature (normal temperature, high temperature, low temperature or variable temperature), Medium (corrosive medium, lubricant).

- Other requirements:such as thermal conductivity, density and magnetic properties.

The performance of the material is determined on the basis of a comprehensive analysis of the working conditions.For example, fatigue performance is required under alternating load, good toughness is required for work under impact load, and corrosion resistance is required for working in corrosive media such as acid and alkali.

- Meet the process performance of the products

Process performance refers to the performance of the material to adapt to processing during the manufacturing process, that is,casting performance, forging performance, welding performance, machining performance and heat treatment process performance.

The quality of the material process performance has a direct impact on the processing and production of the product. Good process performance can not only ensure the manufacturing quality of products, but also help improve productivity and reduce costs.

Therefore, process performance is also a problem that must be considered in material selection.When we are going to choose alloy steel, the specific issues that need to be considered are as follows:

Question One:Does the alloy steel have good casting performance?

Question Two:Does the alloy steel have good pressure processing performance?

Question Three:Does the alloy steel require to have certain weldability?

Question Four:Does the alloy steel need to have good machinability?

Question Five:Does the alloy steel have good heat treatment process performance?

- Meet the economic principle of the products

The principle of economy not only refers to the selection of the cheapest materials or products with the lowest production cost, but also refers to the use of value analysis methods to comprehensively consider the impact of materials on the function and cost of products to achieve the best technical and economic benefits.

For the design and selection of materials, the premise of ensuring economy is accurate calculation, rather than blindly selecting higher-level materials or simply replacing the inferior with the superior.

In addition, suitable materials should be selected according to the stress, temperature, corrosion resistance and other conditions of the product, rather than simply pursuing a certain index.

ALLOY STEEL GRADE LIST

| AISI / SAE | DIN / EN | BS | JIS / KS |

| A182 Grade F11 | 13CrMo44/1.7335 | ||

| A182 Grade F11 | 10CrMo9-10/1.7380 | ||

| 16CrMo44/1.7337 | SCM415 | ||

| 4130 | 25CrMo4/1.7218 | 708A25 / 708M25 | SCM430 |

| 4135 | 34CrMo4/1.7220 | - | SCM435 |

| 4140 | 42CrMo4/1.7225 | 708M40 / EN19 | SCM440 |

| 4150 | 50CrMo4/1.7228 | - | SCM445 |

| 4340 | 34CrNiMo6/1.6582 | 817M40 /EN24 | SNCM439 |

| 5140 | 41Cr4/1.7035 | 530M40 | SCr440 |

| 8620 | 20NiCrMo2-2/1.6523 | 805M20 | SNCM220 |

| 9840 | 36CrNiMo4/1.6511 | 817A37 / 817M37 | - |

| - | 41CrAlMo7/1.8509 | EN41B | SACM645 |