Fuhong Steel is one of leading exporter and supplier specializing in manufacturing, stockholding,exporting special steel raw material .Fuhong supplies a wide range of grades for special steel,Core product is including Engineering steel ,High speed steel, Cold work tool steel, Hot work tool steel, Plastic mould steel etc.

supplier specializing in manufacturing, stockholding,exporting special steel raw material .Fuhong supplies a wide range of grades for special steel,Core product is including Engineering steel ,High speed steel, Cold work tool steel, Hot work tool steel, Plastic mould steel etc.

Founded in 1998,with more than 20 years’ industrial experience,Fuhong are still sticking to offer customers one-stop service and integrated supply chain solutions .Adhering to the business principle of win-win cooperation, Fuhong are not only delivering qualified special steel raw materials and related products, but also delivering competitive advantage to all of customers we are serving in the world.

With independent Laboratory for Elements analysis, Hardness testing, Mechanical testing, Ultrasonic testing,and strict quality control system complied to ISO 9001 certification which makes us supply high quality special steel that meet EN,DIN, AISI/ASTM ,JIS and BS national standard.Fuhong are commited to improve customer service and product quality for all kinds of industries, with advantages of technologies, equipment and price. We serve you with our honesty, integrity, and professionality.We hope our parters grow with us in a health way.

ISO9001:2015 Quality Control

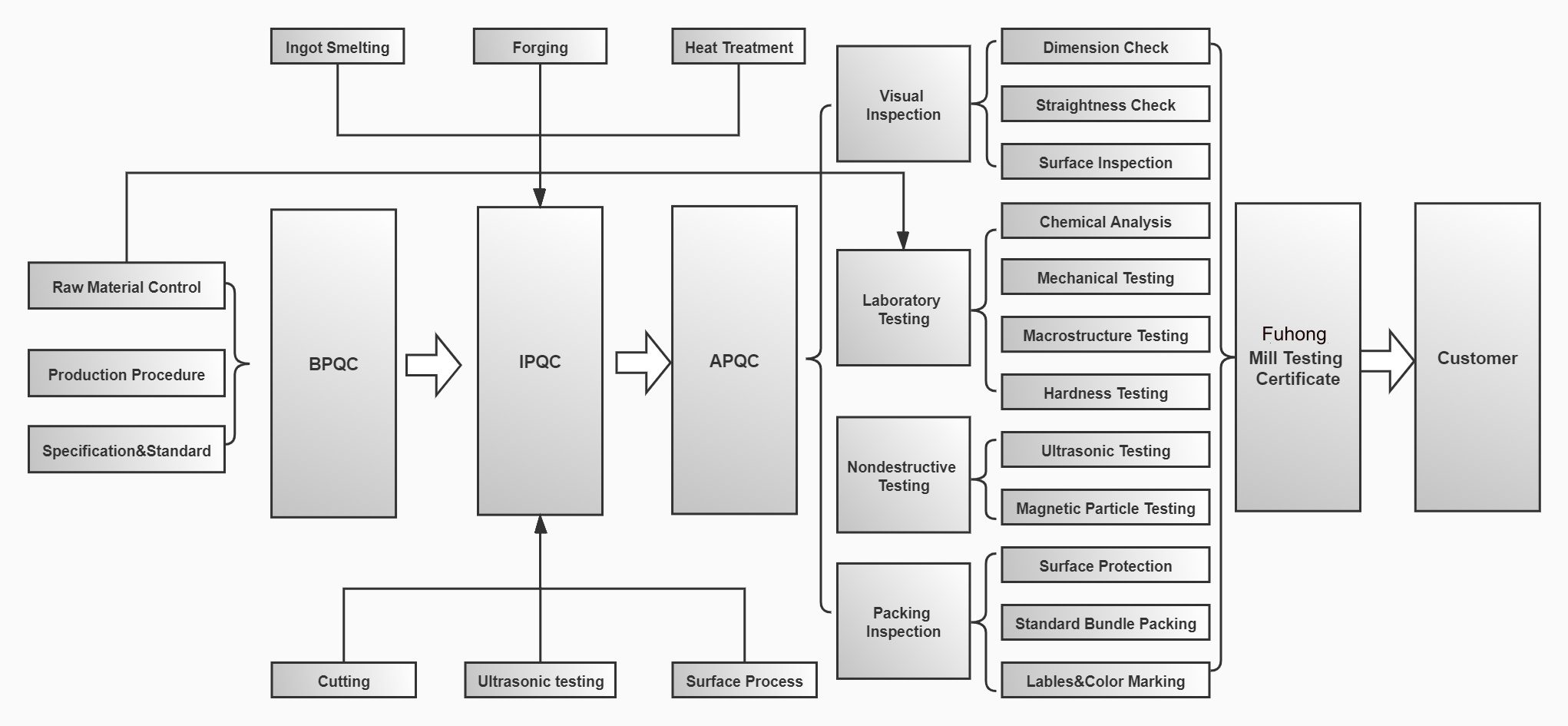

Fuhong firmly believe that “quality is produced, not inspected”,we have established a set of stable and effective quality management system which are carried our strictly as per ISO9001: 2015 standard.Our quality control system is involved in the whole processing from raw material to finished product.With quality management system improvement,it supports Fuhong to reduce actual costs, improve the qulity,and optimize services for our customers.

Fuhong totally understood the importance of maintaining strict and effective quality assurance system.Quality is not only the basis for Fuhong to creat values.but also the life for the Fuhong. It helps us to meet the the potential customer’s requirements,and keep Fuhong on much competitive advantage in the steel industry on higher level.Under continuous-improving quality assurance system, we are not just focusing on quality inspection for final products,but also pay much attention to the quality improvement and upgrading. In order to better control product quality,we are carrying out three steps:Before production quality control(BPQC),During production quality control(DPQC),and After production quality control(APQC).

-

Before Production Quality Control

BPQC:Check the specification and the production techniques to ensure that every production procedure will lead to the proper quality. -

During Production Quality Control

DPQC:According to production procedure,DPQC are carried out to ensure production can meet the designated technical requirements.Do necessary tests during the production. Break point will be carried out in Smelting,Foring,Heat Treatment and Machining procedure. -

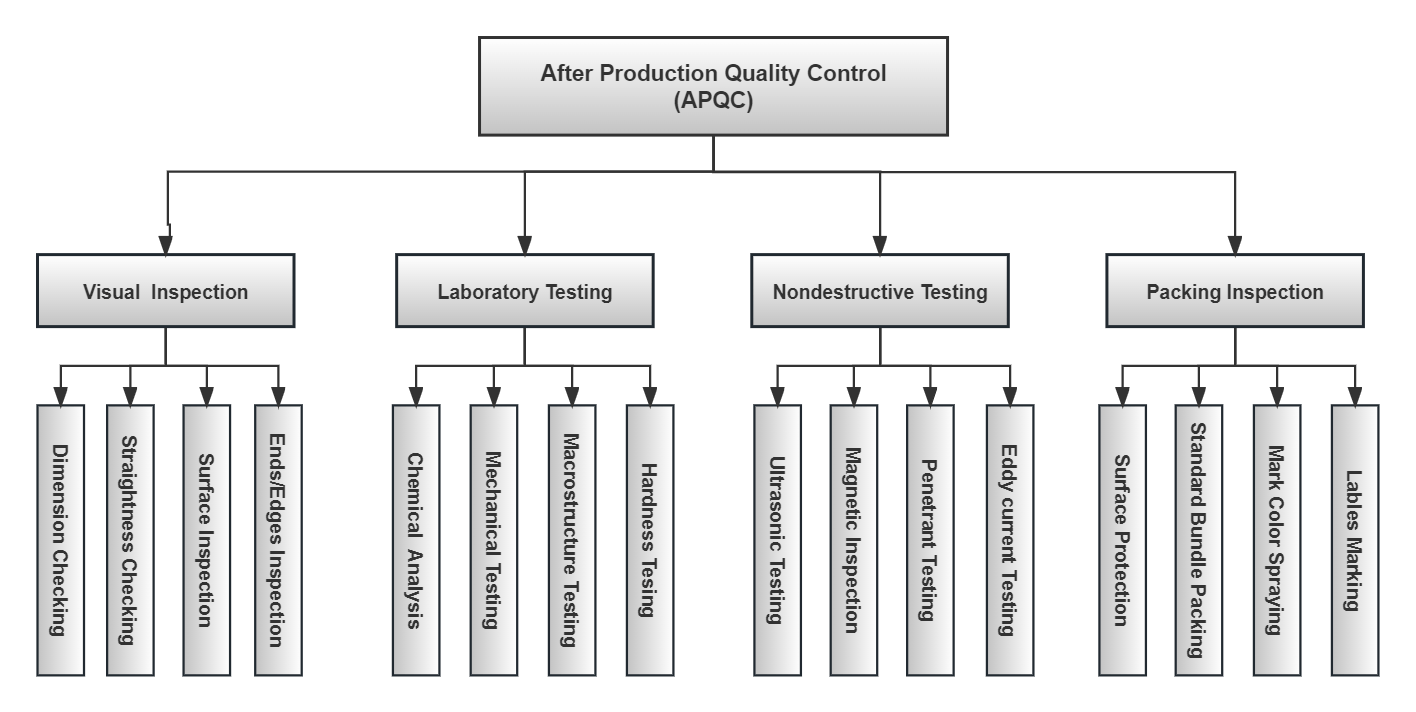

After Production Quality Control

APQC:After the production of products,Fuhong will carry out quality inspection for final products.Testing results for each testing will be recorded to ensure that all products meet customer requirements.