SACM645 NITRIDING STEEL-JIS G4053

SACM645 steel manufacturers and suppliers, supplied in round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

SACM645 steel is defined as Cr-Mo-Al Nitriding steel as per JIS G4053 Standard.It has excellent wear resistance,high surface hardness and fatigue strength after nitriding.This material is generally supplied in annealed condition.SACM645 is usually used for high precision machine parts,typical use are cylinder lining, compressor parts,and hydraulic parts.

SACM645 Steel Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Mo | Al |

| SACM645 | 0.4-0.5 | 0.15-0.5 | ≤ 0.6 | ≤ 0.03 | ≤ 0.03 | 1.3-1.7 | 0.1-0.3 | 0.7-1.2 |

SACM645 Steel Related Specifications

BS:EN41B

DIN/EN:41CrAlMo7/34CrAlMo5

GB:38CrMoAl

ANFOR:40CAD6.12/30CAD6.12

SACM645 Steel Heat Treatment & Mechanical Property

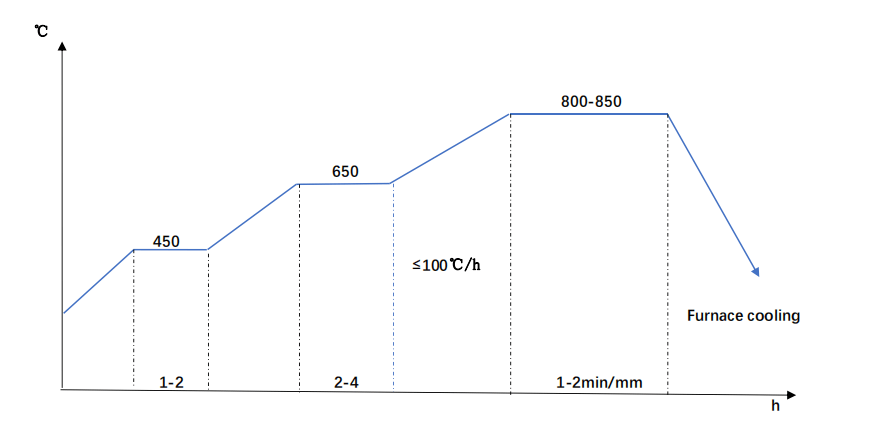

SACM645 Steel Annealing

1.Annealing temperature:800-850℃

2.Three steps for heating uniformly,enough time for temperature holding

3.Cooling in the furnace.

4.Max hardness:229HB

SACM645 Annealing Diagram

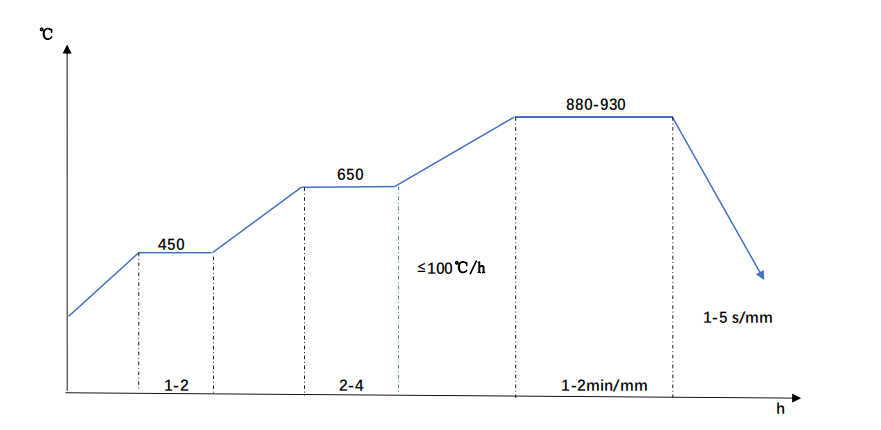

SACM645 Steel Quenching

1.Quench temperature:880-930℃

2.Three steps of temperature raising,holding time for thoroughly heated.

3.Oil quench.

4.Tempering immediately after quenched

SACM645 Steel Quenching Diagram

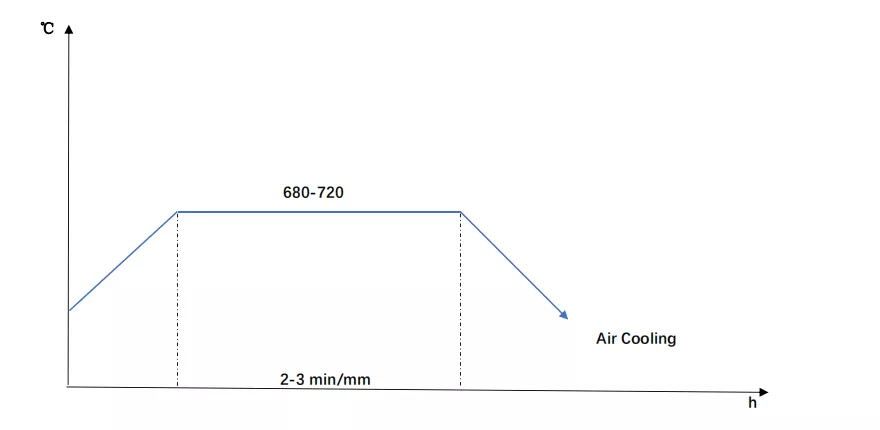

SACM645 Steel Tempering

1.Temper temperature:680-720℃

2.Air cooling.

SACM645 Tempering Diagram

SACM645-Mechanical Property With Quenching and Tempering

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V |

| ≥1000Mpa | ≥850Mpa | ≥15% | ≥50% | ≥90J |

SACM645 Steel Quality Certification

A material test report(Inspection Certificate EN 10204 3.1) will be provided, documenting the following:

1.Chemical analysis

2.Mechanical properties

3.Surface hardness

4.Non metallic inclusion

5.Heat treatment report

6.Grain size

7.Forging ratio

8.Ultrasonic test report

SACM645 Steel Supply Form & Size

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.16 – 130mm with UT Assurance

Heat treatment: Normalizing (+N), Annealing (+A),Quenched and Tempered (+QT)

Surface finish:Black / Rough turned / Peeled