C60 | C60E QUALITY CARBON STEEL

C60/C60E carbon steel manufacturers and suppliers,supplied with round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

C60/C60E carbon steel is a medium carbon steel according to EN standard. It has characteristics similar to that of C55 carbon steel which has high hardness and high strength after hardening.

C60/C60E steel is widely used for less exacting springs, shafts, bushings, crankshafts, etc.

C60/ C60E Steel Chemical Composition

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni | Cr+Mo+Ni |

| C60/1.0601 | 0.57-0.65 | 0.60-0.90 | ≤ 0.045 | ≤ 0.045 | ≤ 0.4 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 | ≤ 0.63 |

| C60E/1.1221 | 0.57-0.65 | 0.60-0.90 | ≤ 0.03 | ≤ 0.035 | ≤ 0.4 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 | ≤ 0.63 |

C60/ C60E Steel Relevant Standards

| USA | UK | China | Japan | Australia |

| 1060 | 070M60 | 60# | S60C | 1060 |

Critical Temperature for Heat Treatment of C60/C60E

- Ac1:727℃

- Ac3:766℃

- Ar1:690℃

- Ar3:743℃

C60/C60E Steel Heat Treatment & Mechanical Property

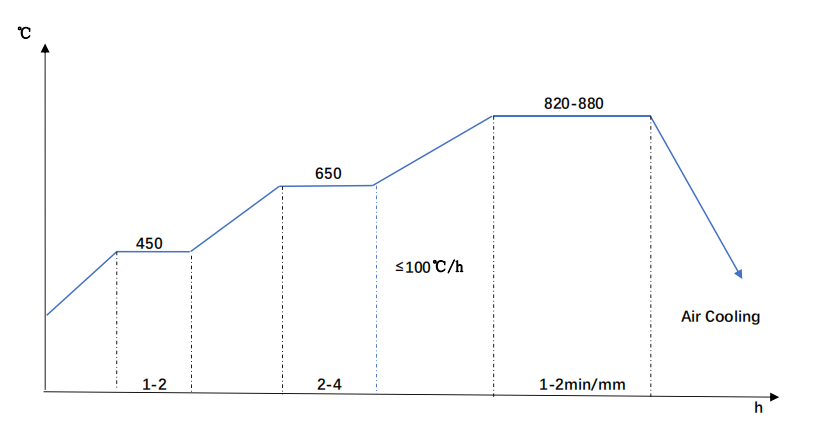

- Normalizing: 820 – 880°C,Cooling in air

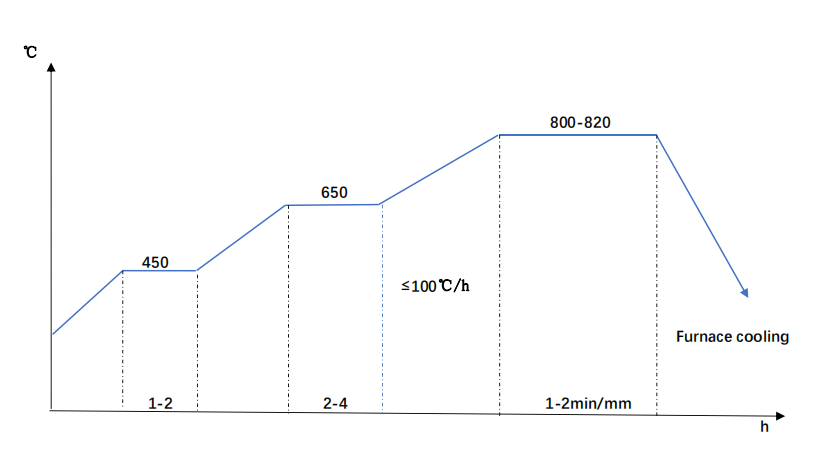

- Annealing:800 – 820°C,Cooling in furnace

- Hardening:800 – 820°C,water quench

- Tempering:380 – 450°C,Cooling in air,40-45HRC.

C60 Steel Normalizing Diagram

C60 Steel Annealing Diagram

C60/C60E Steel Mechanical Properties in Normalized & Annealed condition

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness |

|

| Normalized | 775 Mpa | 420 Mpa | 18% | 37% | 13J | 229 HBW |

| Annealed | 625 Mpa | 370 Mpa | 22.5% | 38% | 11J | 179 HBW |

C60/C60E Steel Hardness Vs Tempering temperature

| Quenching Temperature,℃ | Quenching Hardness,HRC | Temperin Temperature,℃ | 150 | 200 | 300 | 400 | 500 | 550 | 600 | 650 |

| 820 | 62-63 | Hardness,HRC | 63 | 56 | 50 | 45 | 34 | 30 | 24 | 21 |

C60/C60E Steel Mechanical Property with Quenched and Tempered Condition

| Quenching temperature | Tempering temperature | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Impact Charpy-V J |

| 880°C | 150°C | ≥2200 | - | - | ≥34 | - |

C60/C60E Quality Certification

A material test report(Inspection Certificate EN 10204 3.1) will be provided, documenting the following:

1.Chemical analysis

2.Mechanical properties

3.Surface hardness

4.Non Metallic Inclusion

5.Heat Treatment Process

6.Grain size

7.Forging ratio

8.NDE test method/criteria/report

C60/C60E Steel Supply Form & Size

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks,Tubes: Customized or According to Drawing

- Rolled Round Bars: Dia.16 – 350mm with UT Assurance

Heat treatment: Normalizing (+N), Annealing (+A),Q&T

Surface finish:Black / Rough turned / Peeled