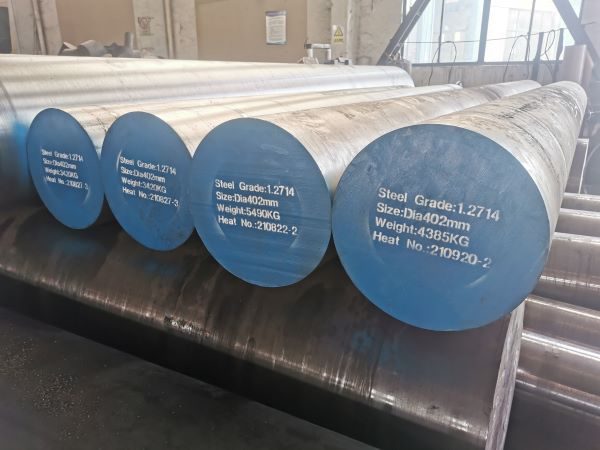

Application of DIN1.2714 steel in industry

1.2714 steel (corresponding to the German DIN standard, also known as 56NiCrMoV7) is a high-strength, high-toughness alloy tool steel, mainly used in industrial scenarios that need to withstand high stress, high temperature and wear. The following are its actual application areas and specific examples:

1. Hot working die field

- Die casting die

High pressure die casting die for aluminum, magnesium and zinc alloys. Its high temperature resistance (about 500°C) can resist the impact and thermal fatigue of molten metal and extend the life of the die. - Hot forging die

During the hot forging process of automotive parts (such as crankshafts and connecting rods), they are subjected to high temperatures and repeated impacts. The high toughness and thermal fatigue resistance of 1.2714 steel ensure the stability of the die. - Extrusion die

Used for hot extrusion molding of copper alloys or aluminum alloys, with excellent high temperature softening resistance.

2. Plastic molding industry

- Injection molds

Suitable for the production of high-precision plastic parts (such as automobile lampshades, electronic housings), especially for complex molds that require rapid cooling. Its high hardness (48-52 HRC) and polishing properties ensure surface finish. - Blow molds

Used to manufacture hollow plastic containers, wear-resistant and able to maintain dimensional stability for a long time.

3. Cold working mold field

- Stamping molds

Used for punching and stretching of steel plates or high-strength materials. Its high toughness can reduce the risk of chipping. - Shearing tools

In continuous shearing operations (such as sheet metal stripping), the wear resistance of 1.2714 steel reduces the frequency of replacement.

4. Special industrial parts

- Aerospace parts

Manufacture of high-temperature resistant fixtures or test equipment components to withstand extreme environments. - Heavy machinery

Used for parts such as gears and shafts that require high fatigue strength, and improve comprehensive performance through heat treatment (quenching + tempering).

5. Advantages and characteristics

- Composition characteristics: Contains chromium (Cr), molybdenum (Mo), nickel (Ni), and vanadium (V), which enhance high temperature strength and wear resistance.

- Heat treatment adaptability: Surface hardness and corrosion resistance can be further improved through surface treatment (nitriding, carburizing).

- Economical: Compared with higher-end materials (such as powder metallurgy steel), it is low-cost and easy to process, suitable for small and medium-sized batch production.

Typical application cases

- Automotive industry: engine cylinder die casting mold, hot forging mold for turbocharger components.

- Electronics industry: mobile phone shell injection mold, connector precision stamping mold.

- Energy industry: wind turbine gear forging mold.

Precautions

- Processing suggestions: Preheating (300-400°C) is required to avoid cracking, and stress relief tempering is required after finishing.

- Maintenance: Regular surface repair (such as laser cladding) can extend the service life of the mold.

In short, 1.2714 steel has become a versatile material choice in the manufacturing industry due to its balanced strength, toughness and heat resistance, especially in medium and high temperature mold scenarios.